Motor/Driver, 90 krpm, 75 W

Background

The motor/driver is designed for small turbomolecular pumps. In such applications a concern is the eddy-current loss on the rotor since the rotor is in vacuum and poorly cooled. Another concern is the size. The motor should be small to fit the space. The driver should be small so that it can be attached to the pump body.

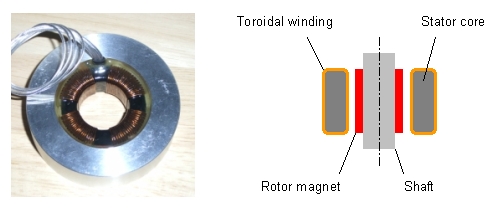

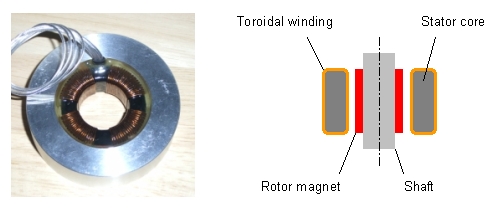

The motor

It is a two-phase BLDC motor (see figure below). At 90 krpm, without forced cooling, the motor is capable of a mechanical power of 75 W (continuous) or 150 W (2 min). The stator has a ring-shaped powder core, giving low iron loss, low eddy-current loss on rotor (owing to slotless), and small size (owing to toroidal winding).

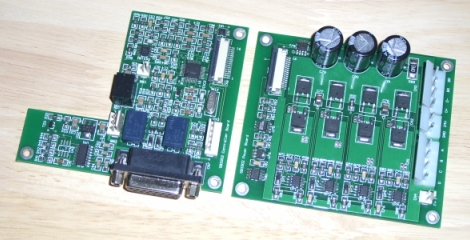

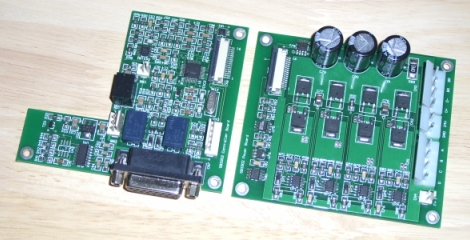

The driver

The driver (see figure below) achieves sensorless operation of the motor, and also performs supervisory control of the pump. The driver has a serial port. Operation can be stand-alone or by sending commands to the driver.