Motor/Driver, 33 krpm, 1200 W

Background

The motor/driver is designed for turbomolecular pumps. In such applications it is a standard practice to limit the dc bus below 100 V. Thus the driver runs on a dc power supply of 96 V even if the power involved is not so small. With a lower bus voltage, motor insulation is easier, the windings have fewer turns, and the switching loss becomes lower. But these are at the price of a bulky switching mode power supply. For other applications the motor/driver can be modified to fit bus voltages directly rectified from the mains.

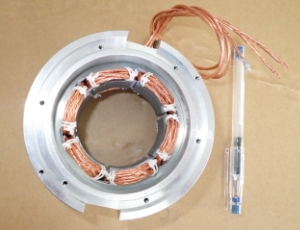

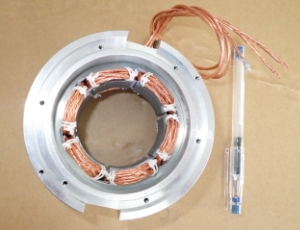

The motor

It is a three-phase fractional-slot concentrated-winding BLDC motor. Shown below is the stator, which has six slots. The stator core has a 55-mm inner diameter, 90-mm outer diameter, and 30-mm axial length. The rotor (not shown) has two pole pairs.

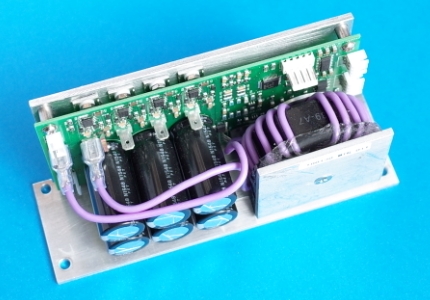

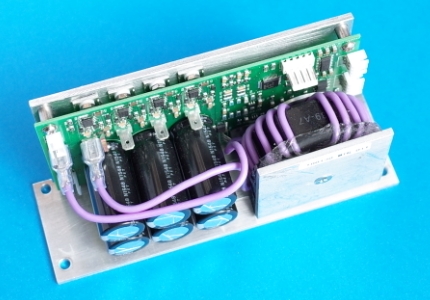

The driver

The driver achieves sensorless operation by detecting the back EMF zero crossing while driving the motor with the six-step commutation sequence. In order to precisely detect the back EMF zero crossing, a synchronous buck circuit (step-down) is used to make the bus voltage variable so that the three-phase full bridge does not need to perform PWM. The driver is operated by a supervisory controller via a serial link. The size is 50×70×130 mm3.